Technical Library

V-belt premature failure and troubleshooting

Premature breakage factors and their countermeasures

| Image | Primary cause | Prevention |

|---|---|---|

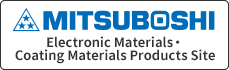

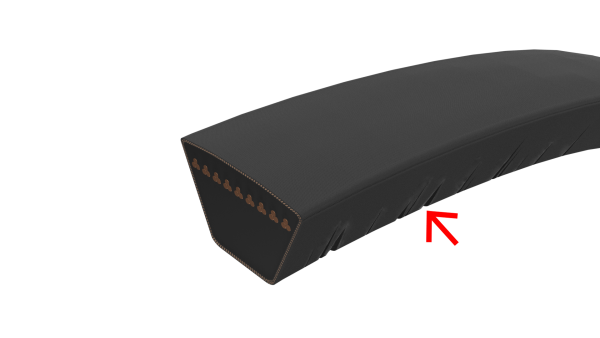

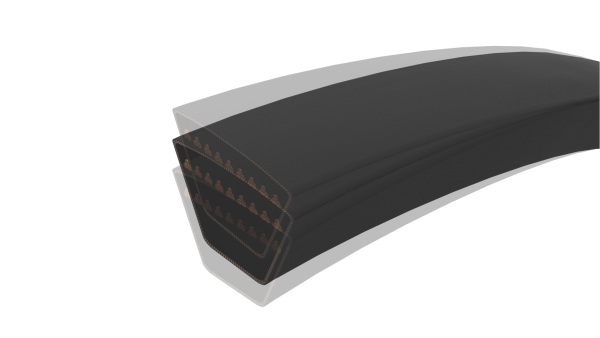

Image: |

Primary cause: 1.Belt Tension Deficiency: This suggests that the tension in the belt is not adequate for its intended use. 2.Overload (Insufficient Number of Belts): This indicates that the belt system is overloaded, likely due to an insufficient number of belts being used for the required task. 3.Small Contact Angle with Pulleys: This refers to a situation where the angle of contact between the belt and the pulleys is too narrow, potentially affecting performance. 4. Adhesion of Oil, Water, etc.: This points to the issue of substances like oil or water adhering to the belt, which can impact its function and efficiency. |

Prevention: 1.Provide Proper Tension: Ensure that the belt is tensioned correctly according to its specifications and intended use. 2.Increase Belt Size or Number of Belts: Consider enlarging the size of the belt or increasing the number of belts used to better distribute the load. 3.Install an Appropriate Idler Pulley on the Loose Side: Place a suitable idler pulley on the side of the belt that is not under tension to improve its performance. 4.Correct the Parallelism of the Pulley Shaft: Adjust the alignment of the pulley shaft to ensure it is parallel, enhancing the belt's operational efficiency. 5.Wipe Off Oil and Water Completely: Remove any oil, water, or other contaminants from the belt thoroughly to prevent slippage and degradation. 6.Install Belt Covers to Prevent Adhesion: Use belt covers to protect the belt from external substances that might adhere to it, such as oil and water. |

| Image | Primary cause | Prevention |

|---|---|---|

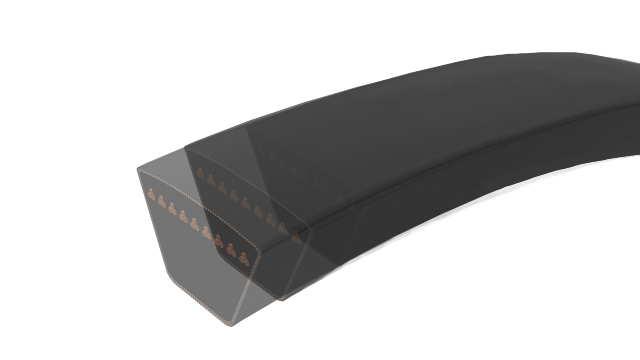

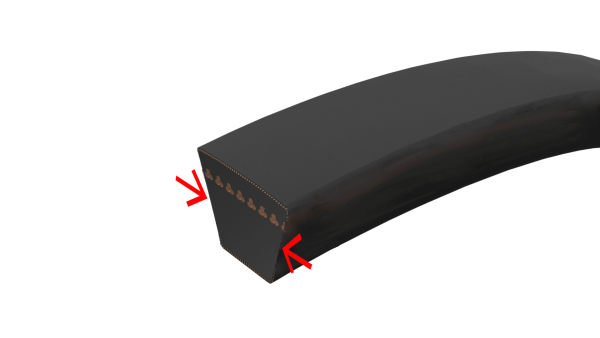

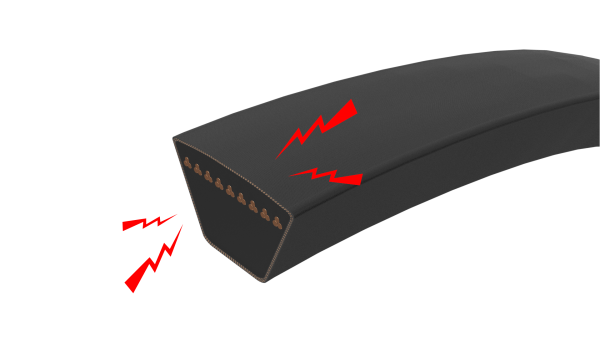

Image: |

Primary cause: 1.Large Load Fluctuations and Shock Loads: Indicates significant variations and sudden impacts in the load that the belt system must handle. 2.Locking Load Pulley: Refers to a situation where the pulley responsible for bearing the load becomes jammed or locked. 3.Biting of Foreign Objects: The intrusion of external objects into the belt system, potentially causing damage or disruption. 4.Overload (Insufficient Number of Belts): A condition where the system is overloaded due to an inadequate number of belts for the required task. 5.High Heat and Bending Fatigue: Indicates issues arising from excessive heat and repeated bending stress on the belt. This can include: ・Small Pulley Diameter and Bending Angle: Problems caused by a pulley diameter that is too small or an improper bending angle of the belt. ・Maximum Rotation Speed: Concerns related to the belt operating at or beyond its maximum safe rotational speed. |

Prevention: 1.Increase Belt Size or Number of Belts: Either enlarge the size of the belt or augment the number of belts in use to better handle the load and distribute it more evenly. 2.Implement Heat Dissipation Measures: Introduce methods or mechanisms to effectively dissipate heat from the belt system, enhancing its performance and longevity. 3.Design Changes: Consider modifications to the system's design, including: ・Pulley Diameter: Adjust the diameter of the pulley to better suit the belt’s operational requirements. |

| Image | Primary cause | Prevention |

|---|---|---|

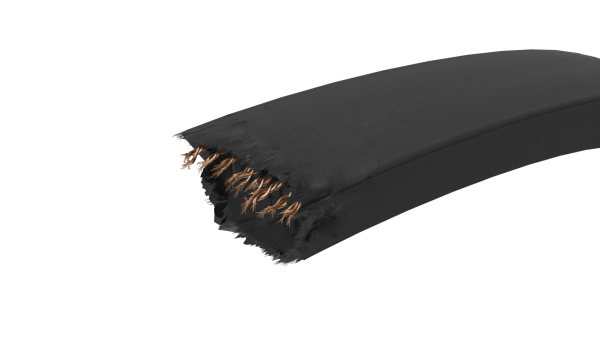

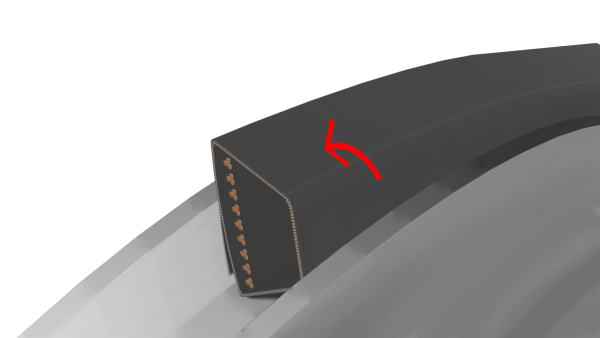

Image: |

Primary cause: 1.Slip Due to Insufficient Belt Tension: This refers to the slippage of the belt as a result of not having enough tension. 2.Use at High Temperatures: Operating the belt in environments with elevated temperatures, which could affect its performance and longevity. 3.Severe Reverse Bending Angles from Undersized Pulley Diameters and Back Tension: Experiencing extreme reverse bending due to the use of pulleys with diameters that are too small, combined with back tension in the system. 4.Exposure to Direct Sunlight: The belt being subject to direct sunlight, which can cause degradation or damage over time. |

Prevention:1.Provide Proper Tension: Ensure that the belt is correctly tensioned according to its specifications and operational requirements. 2.Implement Heat Dissipation Measures: Introduce methods or systems to effectively dissipate heat from the belt, enhancing its performance and durability. 3.Consider Design Changes: Evaluate and, if necessary, modify aspects of the belt system's design to optimize performance and reliability. 4.Install Belt Covers to Shield from Direct Sunlight: Place protective covers over the belt to prevent damage or degradation from prolonged exposure to direct sunlight. |

| Image | Primary cause | Prevention |

|---|---|---|

Image: |

Primary cause: 1.Small Tension Pulley: Indicates that the pulley used for tensioning the belt is smaller than ideal, which may affect the belt's performance. 2.Narrow Reverse Bending Angle: Refers to a situation where the angle at which the belt bends in the reverse direction is too tight, potentially causing stress on the belt. 3.Slip Wear Due to Insufficient Tension: Describes the wear and tear on the belt caused by slippage, which is a result of not having enough tension in the belt system. |

Prevention: 1.Increase the Diameter of the Tension Pulley: Enlarge the diameter of the pulley used for applying tension to the belt to improve its efficiency and reduce stress on the belt. 2.Reduce the Bending Angle: Adjust the bending angle of the belt to be less acute, thereby reducing stress and wear on the belt during operation. 3.Provide Proper Tension: Ensure that the belt is correctly tensioned in accordance with its specifications and operational requirements to prevent slippage and wear. |

| Image | Primary cause | Prevention |

|---|---|---|

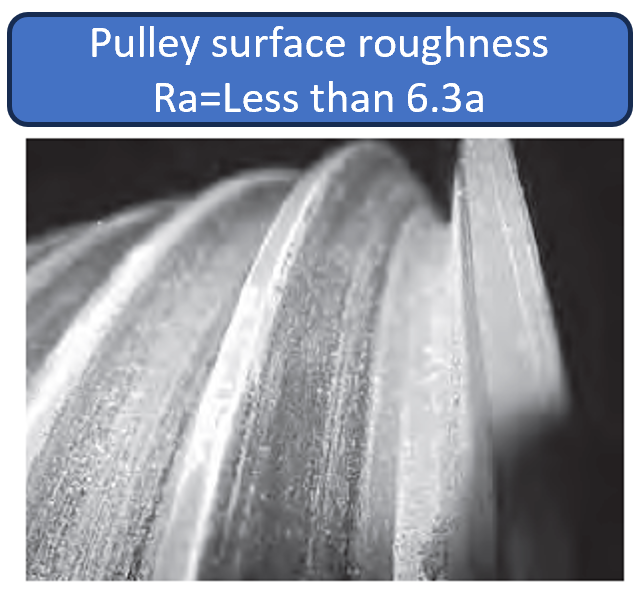

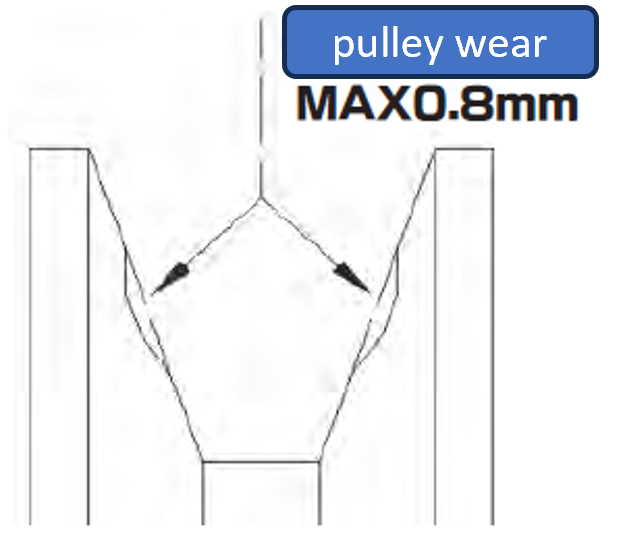

Image: |

Primary cause: 1.Rust or Poor Finishing of Pulley Grooves (Groove Surface Roughness): This refers to the degradation of pulley grooves due to rust or suboptimal finishing, leading to increased surface roughness. 2.Slip Due to Insufficient Belt Tension: Indicates that the belt is slipping because it doesn't have enough tension to maintain proper grip. 3.Slip Due to Excessive Load: Describes slippage occurring as a result of the belt being overloaded beyond its capacity. 4.Significant Misalignment: Points to a major issue where the alignment of the belt system, particularly the pulleys, is far from optimal, potentially causing operational inefficiencies. 5.Pulley Groove Anomaly (Angle, Shape, Scratch): Highlights anomalies in the pulleys, such as improper angles, irregular shapes, or scratches, which can adversely affect the belt's performance. |

Prevention: 1.Evenly Finish the Pulley Groove Surface: Ensure that the surface of the pulley grooves is finished smoothly. (Recommended surface roughness: Ra less than 6.3a.)  2.Provide Proper Tension: Adjust the belt to ensure it is tensioned correctly according to its specifications and operational requirements. 3.Increase Belt Profile Size or Number of Belts: Consider increasing the profile size of the belt or the number of belts used to better distribute the load and improve efficiency. 4.Correct Alignment to Less Than 1/3°: Adjust the alignment of the belt system, aiming for an angular misalignment of less than one-third of a degree to optimize performance. 5.Replace the Pulleys: If anomalies or wear are detected, replace the pulleys to maintain the system's efficiency and prevent further issues.  |

| Image | Primary cause | Prevention |

|---|---|---|

Image: |

Primary cause: 1.Excessive Vibration Due to Resonance: Indicates that vibrations are being amplified within the system, likely due to resonance, which can lead to operational issues or damage. 2.Uneven Belt Length for Multiple Belt Drive: Refers to the problem where belts used in a multi-belt system are not of uniform length, leading to imbalanced operation and increased vibrations. |

Prevention: 1.Increase the Installation Tension: Increase the tension at which the belt was installed to ensure optimal grip and performance. 2.Adjust the RPM: Modify the rotational speed of the belt system to better match operational requirements and reduce stress on the belts. 3.Change the Span Length: This can be achieved by adding idler pulleys or altering the distance between shafts, which can help in optimizing the belt's performance and reducing wear. 4.Uniform Replacement of Multiple Belts: When it's time to replace belts in a multi-belt system, ensure all belts are replaced simultaneously. Using belts of the same type is recommended for consistency and efficiency. |

| Image | Primary cause | Prevention |

|---|---|---|

Image: |

Primary cause: 1.Small Tension Pulley: Indicates that the pulley used for applying tension to the belt is smaller than ideal, which may affect the belt's performance. 2.Narrow Reverse Bending Angle: Refers to a situation where the angle at which the belt bends in the reverse direction is too tight, potentially causing stress on the belt. 3.Slip Due to Insufficient Belt Tension: Describes the wear and tear on the belt caused by slippage, which is a result of not having enough tension in the belt system. |

Prevention: 1.Increase the Diameter of the Tension Pulley: Enlarge the diameter of the pulley used for applying tension to the belt to improve its efficiency and reduce stress on the belt. 2.Reduce the Bending Angle: Adjust the bending angle of the belt to be less acute, thereby reducing stress and wear on the belt during operation. 3.Provide Proper Tension: Ensure that the belt is correctly tensioned in accordance with its specifications and operational requirements to prevent slippage and wear. |

| Image | Primary cause | Prevention |

|---|---|---|

Image: |

Primary cause: 1.Use with Sudden Stop and Start: Operating the belt in conditions where it frequently has to stop and start abruptly, which can stress the belt and cause slippage. 2.Under-Belt Tension: Refers to a scenario where the belt is not tensioned adequately, leading to slippage and reduced efficiency. 3.Overload: Using the belt beyond its rated capacity, which can lead to slippage, premature wear, damage, or failure. 4.Incorrect Belt Selection: Choosing a belt that is not suitable for the specific application or operational requirements, resulting in suboptimal performance and potential slipping noise. |

Prevention: 1.Consider Design Changes or Review Operating Patterns: Evaluate the possibility of altering the design or modifying the operating pattern, such as implementing gradual acceleration and deceleration, to reduce stress and slippage on the belt system. 2.Provide Proper Tension: Ensure that the belt is correctly tensioned according to its specifications and operational needs. 3.Increase Belt Profile Size or Number of Belts: Consider enlarging the size of the belt or increasing the number of belts used to better handle the load and distribute it more evenly. 4.Select Appropriate Belt Specifications and Provide Proper Tension: Choose belts with specifications, shapes, and quantities that suit the conditions of use. Utilize idler pulleys to apply the correct tension to the belts. 5.Uniform Replacement of Multiple Belts: When replacing belts in a multi-belt system, ensure that all belts are replaced simultaneously. The use of belts of the same type is recommended for consistency and better performance. |

| Image | Primary cause | Prevention |

|---|---|---|

Image: |

Primary cause: 1.Belt Overturning Due to Constant Excessive Load: This refers to the belt flipping over as a result of continually being subjected to loads that exceed its capacity. 2.Uneven Belt Length in Multiple Belt Drive: In a system where multiple belts are used, discrepancies in the lengths of these belts can lead to uneven distribution of load and stress, potentially causing the belts to overturn. |

Prevention: 1.Increase Belt Profile Size or Number of Belts: Consider enlarging the profile size of the belt or augmenting the number of belts in use to better distribute the load to prevent flipping belt on its side. 2.Switch to Banded Belts for Multi-Belt Systems: In systems where multiple belts are utilized, transition to using banded belts to ensure uniformity and balanced load distribution. |