Environment

Initiatives to Realize a Resource-Recycling Society

Initiatives to Realize a Resource-Recycling Society

~(3) Development of eco-friendly products~

New lineup of eco-friendly products announced (June 2023)

Mitsuboshi Belting actively works to develop new eco-friendly products that contribute to the realization of a sustainable society and a circular economy.

The Mitsuboshi Belting Group has identified “initiatives for environmental conservation” as one of its material issues, and has set “development of eco-friendly products” as an issue to be addressed to achieve this materiality. We aim to achieve both environmental value and economic value by expanding sales of the new series of eco- friendly products.

Background of development

Companies are expected by society to deliver value through technology and innovation as an important means of realizing a sustainable society. Development of eco-friendly products is one of our key issues for environmental conservation, and we aim to enhance environmental value through the development and sale of such products.

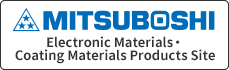

Initiatives to realize a circular economy

The Mitsuboshi Belting Group will contribute to the realization of a resource-recycling society by reducing the environmental impact throughout the product life cycle, through the development and sale of eco-friendly and sustainable belts by actively introducing renewable energy and increasing the proportion of non-petroleum-derived or recycled materials.

The first lineup of new eco-friendly products

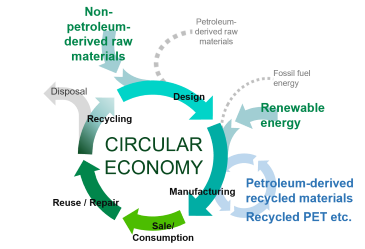

(1) Power transmission belts with a higher proportion of sustainable raw materials

These are next-generation power transmission belts that reduce the proportion of petroleum-derived raw materials and increase the proportion of sustainable materials, such as biomass and recycled materials. As of 2022, we have achieved a sustainable raw material ratio of 32.7%. We aim to increase the ratio to 50% by 2025 and 70% by 2030. |

|

|---|---|

(2) Resin conveyor belt that uses biomass materials, “Biomass Belt”

This is an eco-friendly resin conveyor belt whose surface cover is made of biomass polyurethane manufactured using plant-derived raw materials.There is no difference in physical properties compared to the polyurethane resin used in existing resin conveyor belts, so it can be used with confidence. |

|

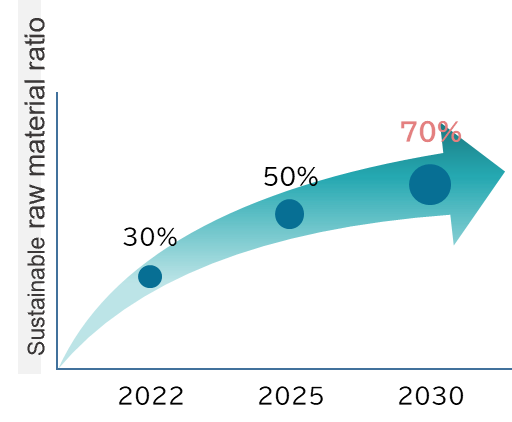

(3) Plant-derived high-performance nylon material “PA410”

PA410 (EcoPaXX®) is a resin material that uses castor oil derived from castor beans for 70% of its raw materials, reducing the proportion of petroleum-derived raw materials.It has the lowest carbon footprint compared to other polyamides and can contribute to the realization of a decarbonized society. |

|